Gelbo Test Blog

Forståelse af Gelbo Flex-testen: Forbedring af emballagens holdbarhed gennem avanceret testning.

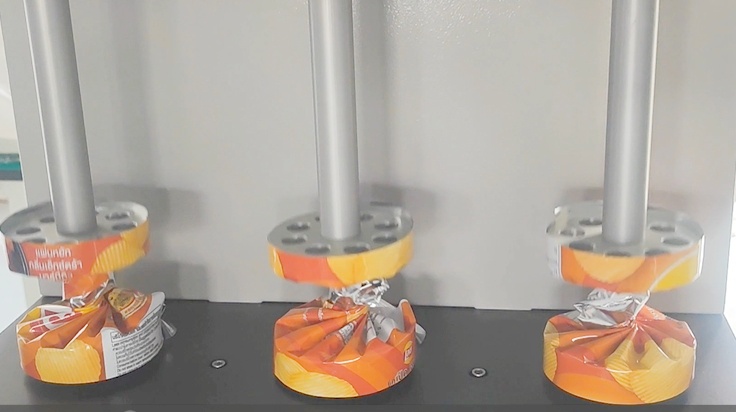

Gelbo Flex Test er et kritisk evalueringsværktøj, der er designet til at simulere de mekaniske belastninger, som barrierefilm udsættes for under transport, håndtering og opbevaring. Ved at udsætte folier for gentagne bøjninger, vridninger og kompressioner måler denne test deres evne til at modstå svigt, hvilket sikrer, at emballagematerialer bevarer deres beskyttende egenskaber gennem hele produktets livscyklus. I brancher som fødevareemballage, medicinsk udstyr og elektronik er denne test afgørende for at garantere, at produkterne forbliver sikre og intakte, uanset hvilke ydre forhold de udsættes for. Find ud af, hvordan Gelbo Flex Test kan forbedre din emballagekvalitet og sikre langvarig pålidelighed.

The Effect of Flexing on Barrier Properties: Gelbo Flex Test and ASTM F392

When it comes to evaluating the durability of flexible packaging materials, particularly those used for barrier protection, it’s critical to assess how repeated flexing impacts

High Barrier Flexible Packaging Gelbo Flex Testing

High Barrier Flexible Packaging Gelbo Flex Testing High barrier flexible packaging plays a critical role in modern packaging systems where oxygen, moisture, light, and aroma

Retort Packaging: Ensuring Flex Durability Using Flex Tester and ASTM F392 Gelbo Flex Method

Retort Packaging: Ensuring Flex Durability Using Flex Tester and ASTM F392 Gelbo Flex Method Retort packaging has become an essential solution for high-temperature food sterilization

ASTM F392: Essential Standard for Flexible Film Flex Durability Testing

Flexible Film Flex Durability Testing ASTM F392 is a critical testing standard in the flexible packaging industry, especially for applications requiring films to resist mechanical

Inner Sealing Layer Durability: Gelbo Test Method & ASTM F392 Explained

Inner Sealing Layer Flex Durability and Barrier Performance In flexible packaging, the inner sealing layer plays a pivotal role in maintaining product integrity, especially during

Meat Vacuum Packaging Flex Durability Testing Using ASTM F392

Vacuum packaging is essential in the meat industry to extend shelf life, preserve freshness, and prevent contamination. However, the performance of meat vacuum packaging depends