ゲルボテストブログ

Gelbo Flex テストを理解する: 高度なテストを通じてパッケージの耐久性を強化。

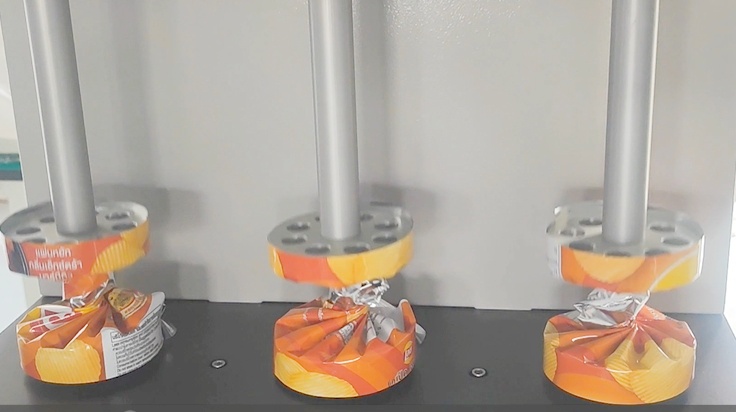

Gelbo Flex Test は、バリアフィルムが輸送、取り扱い、保管中に受ける機械的ストレスをシミュレートするために設計された重要な評価ツールです。フィルムを繰り返し曲げ、ねじり、圧縮することで、このテストはフィルムの破損耐性を測定し、パッケージ材料が製品ライフサイクル全体にわたって保護特性を維持できるようにします。食品パッケージ、医療機器、電子機器などの業界では、外部条件に関係なく製品が安全で無傷であることを保証するためにこのテストが不可欠です。Gelbo Flex Test がパッケージの品質を向上させ、長期的な信頼性を確保する方法を学びます。

The Effect of Flexing on Barrier Properties: Gelbo Flex Test and ASTM F392

When it comes to evaluating the durability of flexible packaging materials, particularly those used for barrier protection, it’s critical to assess how repeated flexing impacts

High Barrier Flexible Packaging Gelbo Flex Testing

High Barrier Flexible Packaging Gelbo Flex Testing High barrier flexible packaging plays a critical role in modern packaging systems where oxygen, moisture, light, and aroma

Retort Packaging: Ensuring Flex Durability Using Flex Tester and ASTM F392 Gelbo Flex Method

Retort Packaging: Ensuring Flex Durability Using Flex Tester and ASTM F392 Gelbo Flex Method Retort packaging has become an essential solution for high-temperature food sterilization

ASTM F392: Essential Standard for Flexible Film Flex Durability Testing

Flexible Film Flex Durability Testing ASTM F392 is a critical testing standard in the flexible packaging industry, especially for applications requiring films to resist mechanical

Inner Sealing Layer Durability: Gelbo Test Method & ASTM F392 Explained

Inner Sealing Layer Flex Durability and Barrier Performance In flexible packaging, the inner sealing layer plays a pivotal role in maintaining product integrity, especially during

Meat Vacuum Packaging Flex Durability Testing Using ASTM F392

Vacuum packaging is essential in the meat industry to extend shelf life, preserve freshness, and prevent contamination. However, the performance of meat vacuum packaging depends