Blog testa Gelbo

Razumevanje testa Gelbo Flex: izboljšanje vzdržljivosti embalaže z naprednim testiranjem.

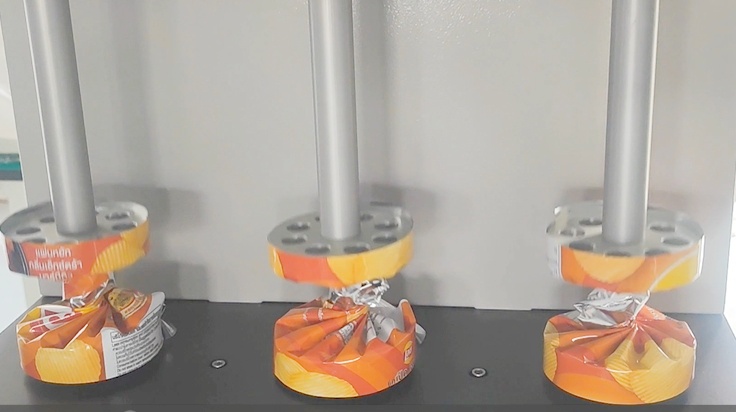

Gelbo Flex Test je kritično orodje za ocenjevanje, zasnovano za simulacijo mehanskih obremenitev, ki jih pregradne folije prenašajo med prevozom, rokovanjem in shranjevanjem. Z izpostavljanjem filmov ponavljajočemu se upogibanju, zvijanju in stiskanju ta test meri njihovo sposobnost odpornosti proti okvaram, kar zagotavlja, da embalažni materiali ohranijo svoje zaščitne lastnosti v celotnem življenjskem ciklu izdelka. V panogah, kot so pakiranje hrane, medicinske naprave in elektronika, je ta test bistvenega pomena za zagotavljanje, da izdelki ostanejo varni in nedotaknjeni, ne glede na zunanje pogoje, s katerimi se soočajo. Naučite se, kako lahko Gelbo Flex Test izboljša kakovost vaše embalaže in zagotovi dolgotrajno zanesljivost.

The Effect of Flexing on Barrier Properties: Gelbo Flex Test and ASTM F392

When it comes to evaluating the durability of flexible packaging materials, particularly those used for barrier protection, it’s critical to assess how repeated flexing impacts

High Barrier Flexible Packaging Gelbo Flex Testing

High Barrier Flexible Packaging Gelbo Flex Testing High barrier flexible packaging plays a critical role in modern packaging systems where oxygen, moisture, light, and aroma

Retort Packaging: Ensuring Flex Durability Using Flex Tester and ASTM F392 Gelbo Flex Method

Retort Packaging: Ensuring Flex Durability Using Flex Tester and ASTM F392 Gelbo Flex Method Retort packaging has become an essential solution for high-temperature food sterilization

ASTM F392: Essential Standard for Flexible Film Flex Durability Testing

Flexible Film Flex Durability Testing ASTM F392 is a critical testing standard in the flexible packaging industry, especially for applications requiring films to resist mechanical

Inner Sealing Layer Durability: Gelbo Test Method & ASTM F392 Explained

Inner Sealing Layer Flex Durability and Barrier Performance In flexible packaging, the inner sealing layer plays a pivotal role in maintaining product integrity, especially during

Meat Vacuum Packaging Flex Durability Testing Using ASTM F392

Vacuum packaging is essential in the meat industry to extend shelf life, preserve freshness, and prevent contamination. However, the performance of meat vacuum packaging depends